Unlocking the Current State and Significance of Vision Guided Robotics

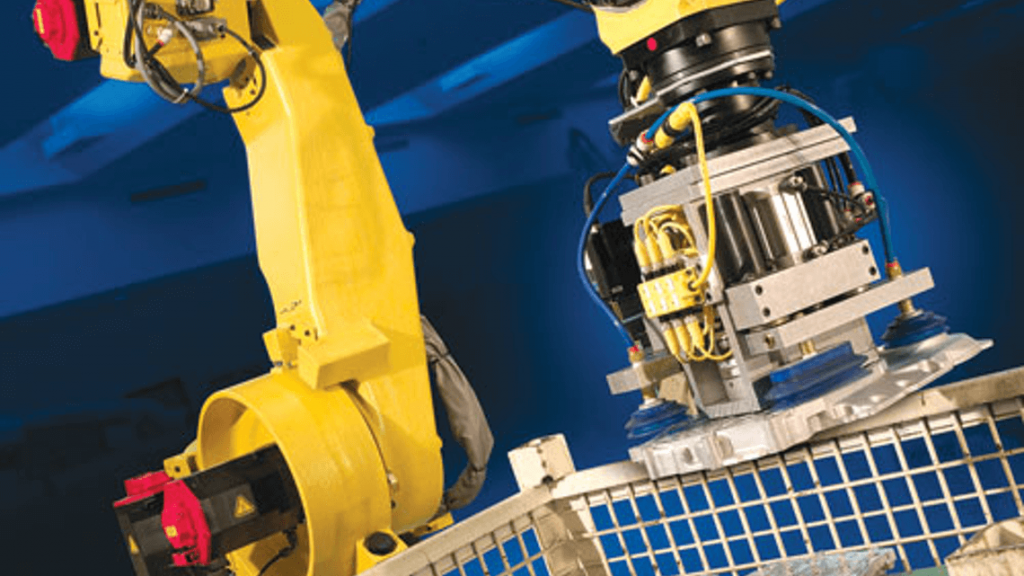

Automation technology has significantly advanced over the last few years, making things easier and convenient for businesses. Robots, in this way, have emerged as an effective solution within sophisticated areas and have become fast, more precise and more capable of automating various numbers of tasks. When integrating this automation solution with vision technology, it becomes cheaper, faster and more intelligent. However, this has led the new way of automation in manufacturing with vision guided robotics (VGR), consisting of technologies needed to classify, process and control objects based on visual data, such as lighting, cameras and software to provide reference points for the robot.

Applications of vision guided robotics are rapidly becoming widespread thanks to the steadily decreasing cost of the latest technology. In today’s advanced world, rapid innovations are introducing sophisticated technologies for vision guided robotics, taking robot functionality to the next level. Earlier, for conventional robots, picking and placing a random part from a bin on time wasn’t an easy task. However, with the evolution of next-gen imaging systems, combined with the availability of more compact, highly efficient and less expensive robots, sensors and advanced technologies, it has become easier to deploy robotic solutions for a large range of applications, particularly within small and mid-size manufacturing companies.

Moreover, as manufacturers consider the potential of Industry 4.0, machine vision for industrial robotic guidance remains to be critical allowing technology to understand the diverse needs of flexible automation and smart manufacturing. This is when the technologies and tools for vision guided robotics are providing their full potential. Most manufacturing companies in the past had refused the use of robotics but thanks to the advancements in precision and accuracy of machine vision, they are now looking to leverage this for a new opportunity.

While manufacturers seek to use vision guided robotics, majorly for a pick and place application, they must first consider the 2D vision system. This can often be a more reasonable and more affordable option, compared with 3D vision. Despite its increasing capabilities, the 2D vision system still requires a traditional lighting source, availability of contrast and color, and slower processing speeds than 3D imaging.

Demands of Vision Guided Robotics from End-Users

Since vision guided robotics applications are quickly becoming common, the demand for this technology from customers is upsurging more than ever. This enhanced demand helps define the future of the technology. Also, customers are demanding a number of capabilities from their VGR technology, including random picking that can replace dedicated operators and simplify the assembly line; the ability to pick and place objects with variations in part orientation in location to minimize costs associated with fixtures; higher flexibility; and high integration.

These requirements from end-users create opportunities to drive technological innovation and for manufacturers and suppliers of vision guided robotics, it paves ways to come up with their abilities to meet these demands.

Considering a report from market research firm Allied Market Research, the global market of Vision Guided Robotics was noted at US$3,834 million in 2015 and is expected to rise to US$7,718 million by 2022, at a growing CAGR of 10.7 percent.

Share This Article

Do the sharing thingy